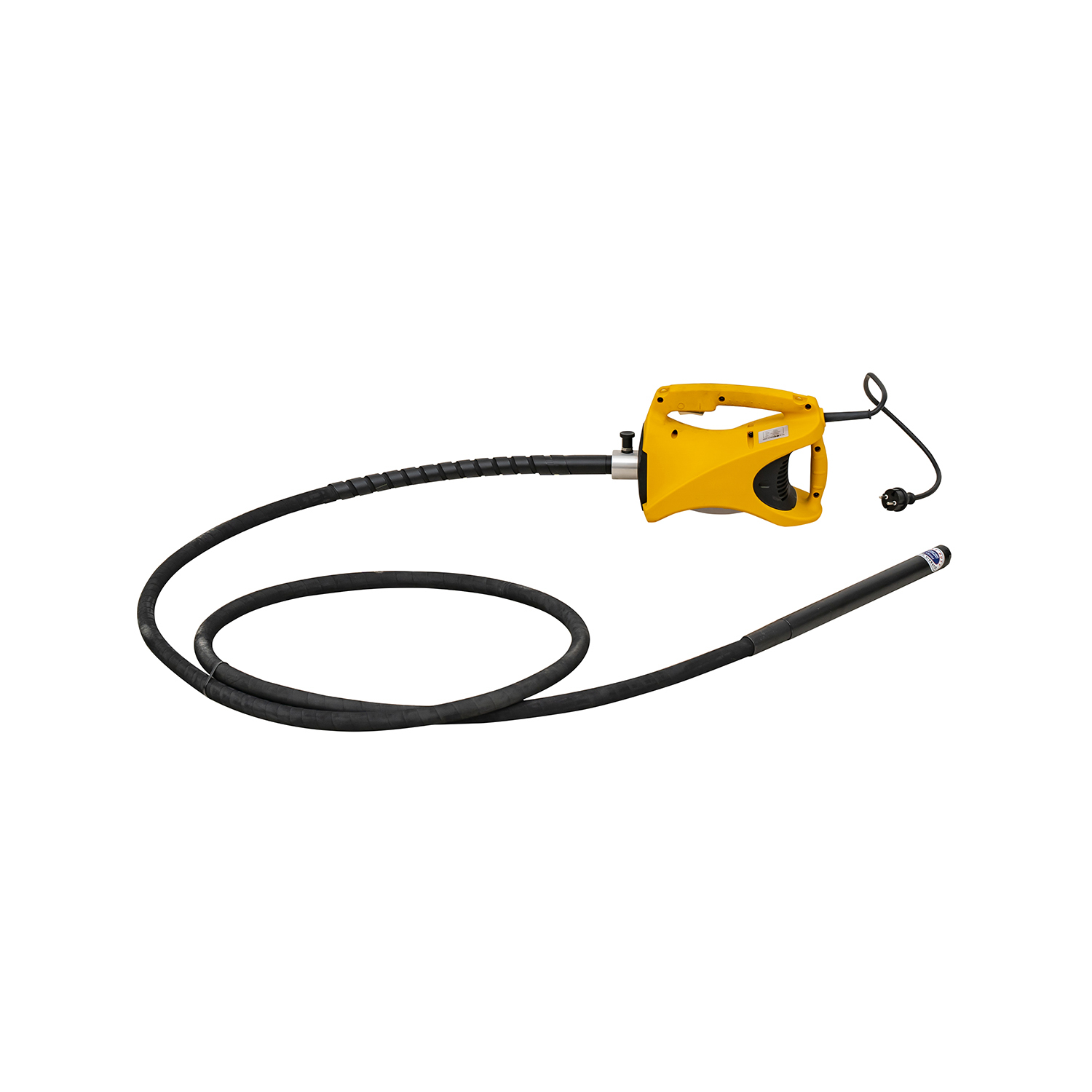

Cheap Concrete Vibarator

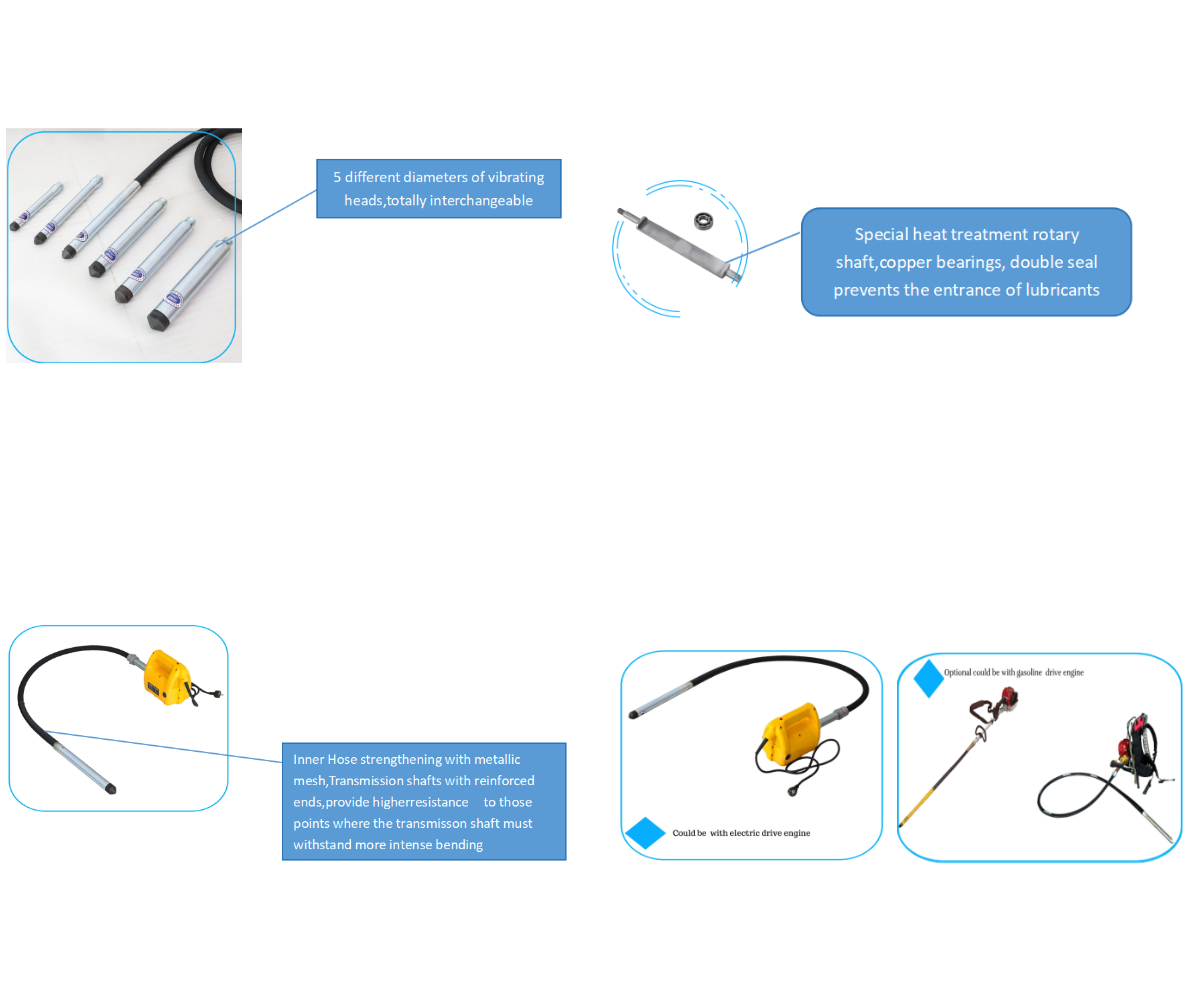

1.5 different diameters of vibrating heads,total interchangeable.Easy interchanges of flexible shafts and vibrator heads

2.Eccentric oversized steel and treated steel end

3.Transmission shafts with reinforced ends,provide higher resistance to those points where the transmission shafts must withstand more intense bending

Product Introduction

The Concrete Table Vibrator is a high-efficiency concrete compaction machine specifically designed for precast concrete production and laboratory testing. By generating uniform and powerful vibrations through an eccentric motor system, it effectively removes air bubbles from concrete mixtures, ensuring dense internal structure, smooth surfaces, and consistent product quality.

Compared with handheld or internal vibrators, the table vibrator provides stable, evenly distributed vibration, making it ideal for molds, test specimens, blocks, slabs, tiles, and other precast concrete components. Its robust structure and reliable vibration performance allow continuous operation in demanding production environments.

Detail

Key Features of Concrete Table Vibrator

Multiple Vibration Motor Options

Equipped with high-quality eccentric vibration motors that deliver stable frequency and amplitude, ensuring uniform compaction across the entire table surface.

Strong & Durable Steel Structure

Manufactured with thick steel plates and reinforced frames, providing excellent load-bearing capacity and long service life under continuous vibration.

Efficient Air Bubble Removal

Powerful vibration force allows concrete to fully fill molds, reducing honeycombing and improving density, strength, and surface finish.

Modular & User-Friendly Design

Simple structure enables quick installation, easy operation, and convenient maintenance without the need for complex tools.

Sealed Components for Harsh Environments

Vibration motors and key components feature sealed designs to resist dust, moisture, and concrete slurry, ensuring reliable long-term performance.

Applications of Concrete Table Vibrator

Precast Concrete Elements

Suitable for blocks, slabs, panels, pipes, tiles, and other precast components.Concrete Test Specimens

Widely used in laboratories for compacting cube, cylinder, and prism samples.Industrial Flooring & Small Precast Parts

Ensures uniform compaction and smooth finishes for flat or shallow molds.Construction & Infrastructure Support

Ideal for workshops producing concrete products for bridges, tunnels, culverts, and retaining structures.Commercial & Residential Precast Projects

Suitable for various concrete mixes and production scales.

Our company and workshop

About Us

Liaocheng Yangfine Machinery Co., Ltd. is located in Liaocheng High-Tech Zone, a well-known industrial city in northern China, covering more than 50 acres with modern workshops totaling 15,000 square meters. The company is equipped with dozens of high-precision CNC machining machines and advanced production facilities.

Based on advanced Korean technology, we specialize in the design and manufacturing of concrete vibration equipment and light construction machinery, including concrete table vibrators, internal concrete vibrators, floor saws, plate compactors, and flexible shaft pumps. With over ten years of continuous development and innovation, we have obtained multiple product patents and achieved ISO 9001 and CE certifications.

Our products are exported to Europe, the United States, Southeast Asia, the Middle East, and North & South America, earning strong recognition for quality, durability, and stable performance.

Our package

Why Choose Our Concrete Table Vibrator?

Uniform and efficient vibration for consistent concrete compaction

Strong steel structure designed for long-term industrial use

Reliable vibration motors with stable performance

Simple operation with low maintenance requirements

OEM customization available for table size, motor power, and voltage

Fast global delivery and professional technical support

Our certificate

FAQ – Concrete Table Vibrator

Q1: What is the MOQ?

A: No MOQ requirement. One unit is available.

Q2: How are the products packed?

A: Generally packed in wooden cases or pallets to ensure safe transportation.

Q3: What are your payment terms?

A: T/T 30% deposit and 70% balance before delivery. Product and packing photos will be provided before final payment.

Q4: What delivery terms are supported?

A: EXW, FOB, CFR, CIF, DDU.

Q5: What is the delivery time?

A: Usually within one month.

Q6: Can you manufacture according to samples or drawings?

A: Yes, OEM and custom production are supported.

Q7: Do you test all products before shipment?

A: Yes, 100% inspection before packaging.