Custom Flexible Drive Shafts

1. 32 Years experience .Can accept specialized customized products

2. Low MOQ.Short delivery time

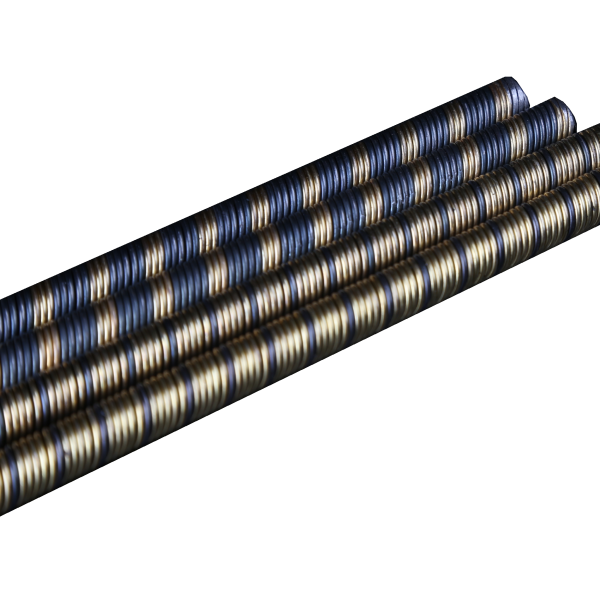

3. Smooth,flexible ,high elasticity.wear-resisting

Product Introduction

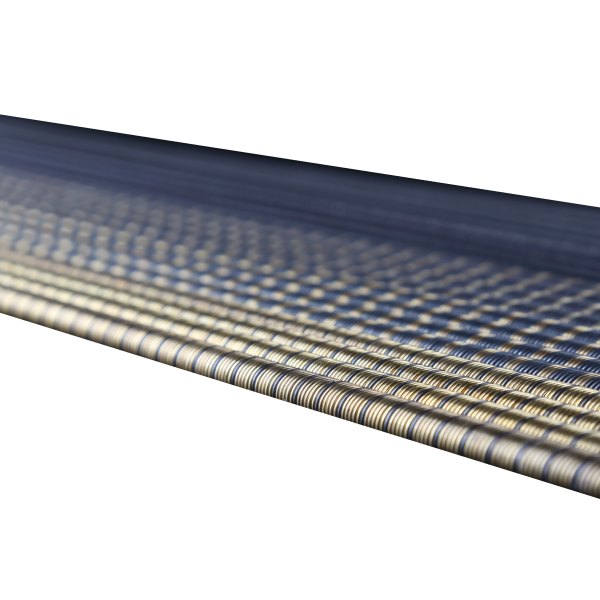

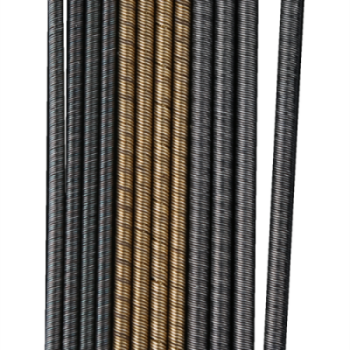

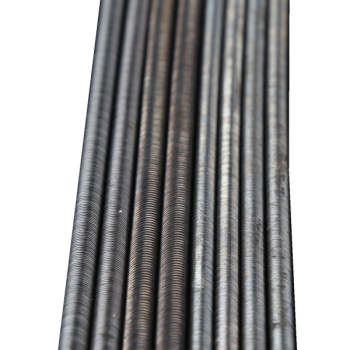

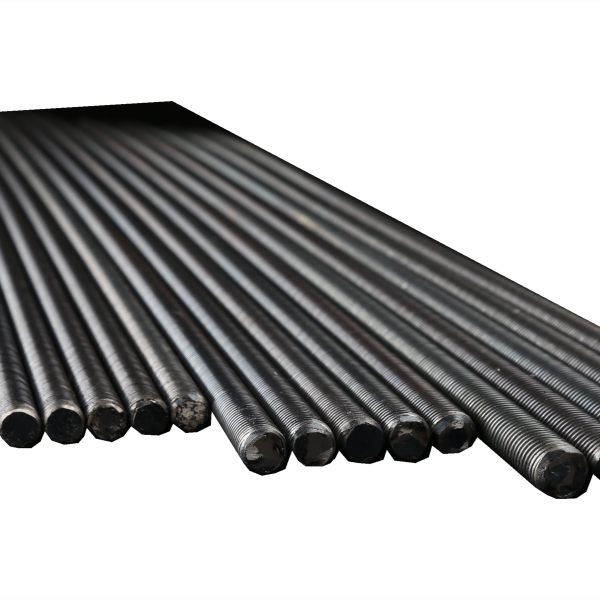

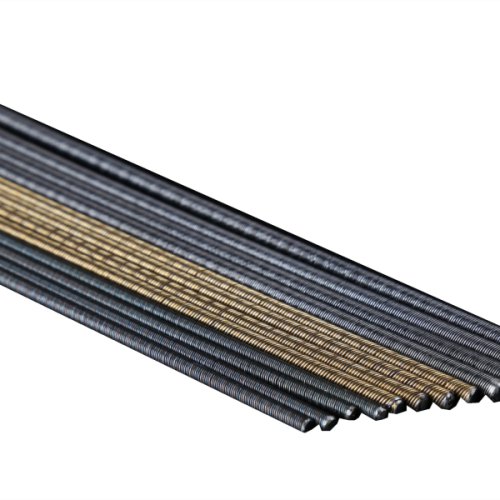

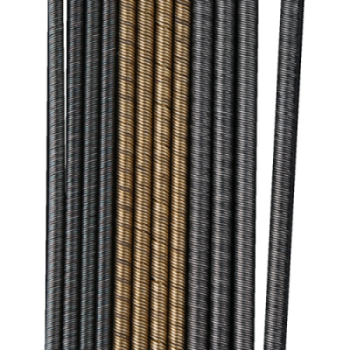

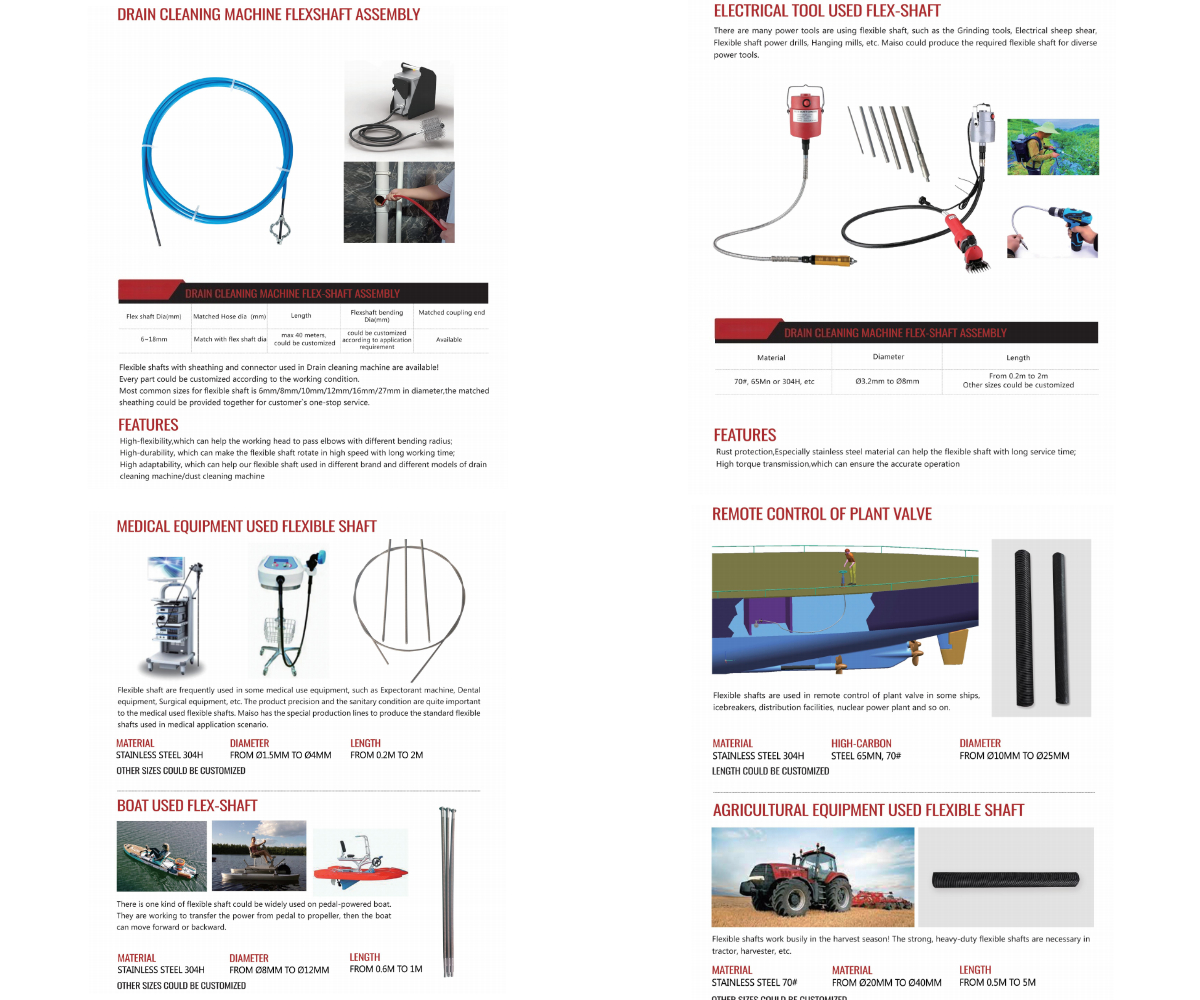

Our Custom Flexible Drive Shafts are high-performance, precision-engineered transmission components designed to deliver efficient rotary power in applications that require exceptional flexibility, durability, and smooth operation. Manufactured from premium materials and tailored to specific customer requirements, these flexible shafts provide outstanding wear resistance, high elasticity, and superior bending performance.

Engineered for demanding industrial and construction environments, our custom flexible drive shafts ensure stable torque transmission even under continuous bending and high-load conditions. They are widely used in concrete vibrators, submersible pumps, power tools, and other rotating equipment, offering reliable, long-term performance and extended service life.

PRODUCT SPECIFICATION PARAMETER FOR PART OF OUR PRODUCTS | ||||||

Flexible shaft | Material | Tolerance(mm) | Bending Diameter (mm) | Layer | Max Failure Torque | Weight |

0.9 | 304 stainless steel wire | (-0.05, 0) | 10-20 | 3 layers 1 core | 0.5 | 0.0036 |

1.5 | 304 stainless steel wire | (-0.1, 0) | 20-30 | 3 layers 1 core | 1.05 | 0.0100 |

2 | 304 stainless steel wire | (-0.1, 0) | 30-40 | 3 layers 1 core | 1.3 | 0.0178 |

3.2 | brass coated steel wire | (-0.1, 0) | 40-60 | 4 layers 1 core | 2.8 | 0.0457 |

4 | 304 stainless steel wire | (-0.1, 0) | 60-80 | 4 layers 1 core | 5.2 | 0.0714 |

5 | 70#/65Mn | (-0.12, 0) | 80-100 | 4 layers 1 core | 6.8 | 0.1116 |

5.2 | 304 stainless steel wire | (-0.12, 0) | 80-100 | 5 layers 1 core | 6 | 0.1207 |

6(normal) | 70#/65Mn | (-0.15, 0) | 90-110 | 6 layers 1 core | 6.6 | 0.1606 |

6.35 | 70#/65Mn | (-0.15, 0) | 140-160 | 4 layers 1 core | 15 | 0.1799 |

6.5 | brass coated steel wire | (-0.15, 0) | 100-120 | 7 layers 1 core | 9.5 | 0.1885 |

7 | 304 stainless steel wire | (-0.15, 0) | 140-160 | 5 layers 1 core | 16 | 0.2186 |

8(all black) | 70#/65Mn | (-0.15, 0) | 100-120 | 5 layers 1 core | 37 | 0.2856 |

8(5 brass coated | brass coated steel wire+70# | (-0.15, 0) | 140-160 | 5 layers 1 core | 30 | 0.2856 |

9 | 70#/65Mn | (-0.15, 0) | 180-200 | 4 layers 1 core | 42 | 0.3614 |

9.15(high speed) | 70#/65Mn | (-0.15, 0) | 240-260 | 5 layers 1 core | 45 | 0.3736 |

9.5(all brass coated) | brass coated steel wire+70# | (-0.15, 0) | 150-180 | 6 layers 1 core | 50 | 0.4027 |

10(normal) | 70#/65Mn | (-0.18, 0) | 240-260 | 4 layers 1 core | 50 | 0.4462 |

12(normal) | 70#/65Mn | (-0.18, 0) | 250-270 | 5 layers 1 core | 70 | 0.6425 |

13(normal) | 70#/65Mn | (-0.18, 0) | 260-280 | 5 layers 1 core | 110 | 0.7541 |

14(normal) | 70#/65Mn | (-0.18, 0) | 280-300 | 5 layers 1 core | 90 | 0.8746 |

15(normal) | 70#/65Mn | (-0.18, 0) | 320-340 | 5 layers 1 core | 120 | 1.0040 |

16(normal) | 70#/65Mn | (-0.18, 0) | 340-360 | 5 layers 1 core | 180 | 1.1423 |

18(normal) | 70#/65Mn | (-0.18, 0) | 450-480 | 5 layers 1 core | 210 | 1.4457 |

20(normal) | 70#/65Mn | (-0.25, 0) | 650-700/1000-1100 | 5 layers 1 core | 360 | 1.7848 |

22(normal) | 70#/65Mn | (-0.25, 0) | 1000-1100 | 5 layers 1 core | 400 | 2.1596 |

25 | 70#/65Mn | (-0.2,0.3) | 900-1100 | 10 layers 1 core | 570 | 2.7888 |

26 | 70#/65Mn | (-0.3,0.3) | 900-1100 | 7 layers 1 core | 950 | 3.0163 |

27(normal) | 70#/65Mn | (-0.5,0) | 900-1100 | 7 layers 1 core | 520 | 3.2528 |

32(normal) | 70#/65Mn | (-0.5,0) | 1000-1200 | 9 layers 1 core | 680 | 4.5691 |

40 | 70#/65Mn | (-0.5,0) | 1000-1200 | 10 layers 1 core | 800 | 7.1392 |

48 | 70#/65Mn | (-1, 0) | 1000-1200 | 12 layers 1 core | 1500 | 10.2804 |

Applications

Our workshop

Key Advantages

Stable Power Transfer

Optimized internal structure ensures consistent torque transmission with minimal vibration, even under high-load or offset conditions.Durable Construction

Advanced material selection and precision processing enhance resistance to abrasion, fatigue, and harsh working environments.Flexible Customization

Shaft dimensions, end fittings, and performance parameters can be customized to meet diverse application needs.Efficient Supply Capability

Low minimum order quantities and streamlined production processes enable fast turnaround and flexible sourcing.Convenient Servicing

User-friendly design allows quick installation, removal, and replacement, reducing downtime and maintenance costs.

Our package

Why Choose Us?

Contact With Us