Flexible Drive for Electric Drill

1. 32 Years experience .Can accept specialized customized products

2. Low MOQ.Short delivery time

3. Smooth,flexible ,high elasticity.wear-resisting

Product Introduction

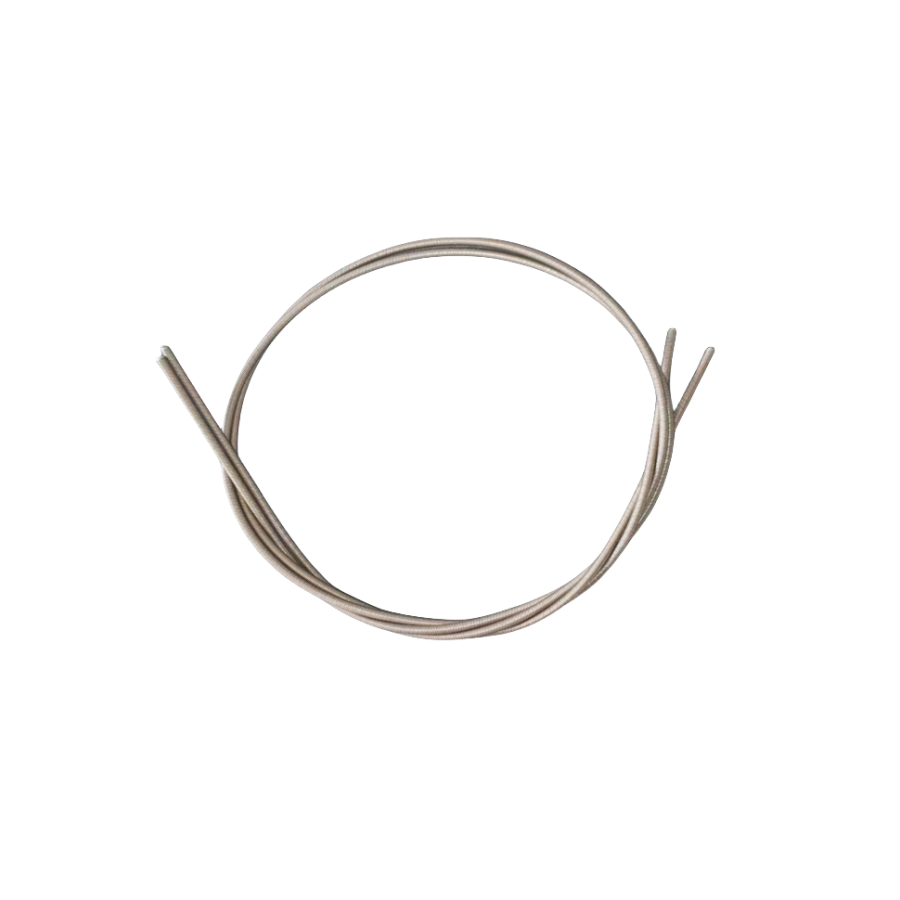

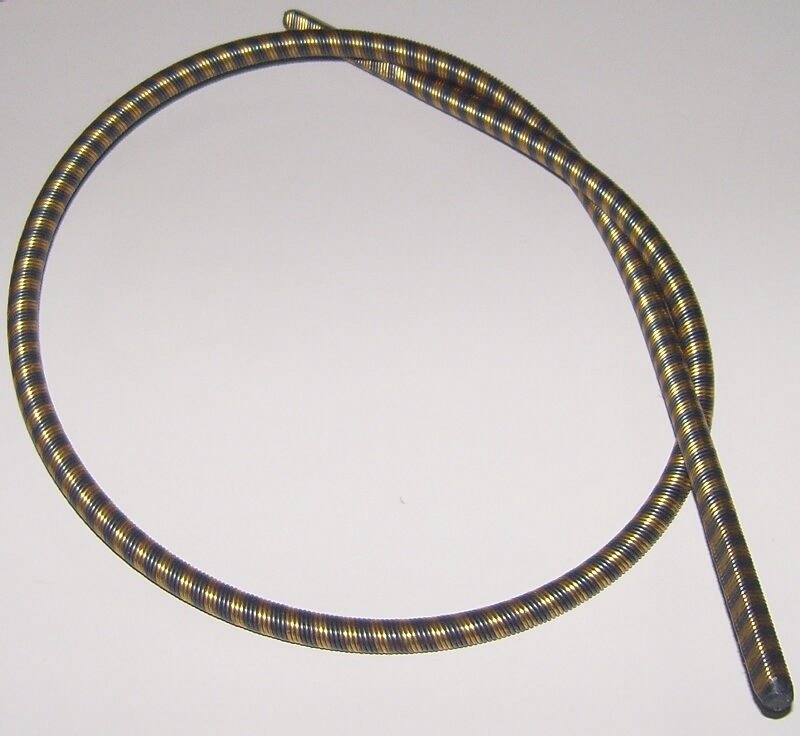

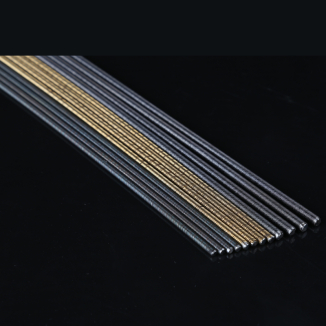

The Flexible Drive for Electric Drill is a high-performance rotary transmission accessory designed to extend the reach and versatility of electric drills in confined, angled, or hard-to-access working areas. Engineered for smooth power delivery and exceptional flexibility, this flexible drive shaft allows efficient torque transfer from the drill motor to the working end without power loss.

Manufactured from premium-grade materials, our flexible drill drive ensures durability, wear resistance, and stable performance under continuous rotation. It is widely used with electric drills for applications such as drilling, grinding, polishing, deburring, and light-duty fastening across construction, manufacturing, maintenance, and DIY projects.

PRODUCT SPECIFICATION PARAMETER FOR PART OF OUR PRODUCTS | ||||||

Flexible shaft | Material | Tolerance(mm) | Bending Diameter (mm) | Layer | Max Failure Torque | Weight |

0.9 | 304 stainless steel wire | (-0.05, 0) | 10-20 | 3 layers 1 core | 0.5 | 0.0036 |

1.5 | 304 stainless steel wire | (-0.1, 0) | 20-30 | 3 layers 1 core | 1.05 | 0.0100 |

2 | 304 stainless steel wire | (-0.1, 0) | 30-40 | 3 layers 1 core | 1.3 | 0.0178 |

3.2 | brass coated steel wire | (-0.1, 0) | 40-60 | 4 layers 1 core | 2.8 | 0.0457 |

4 | 304 stainless steel wire | (-0.1, 0) | 60-80 | 4 layers 1 core | 5.2 | 0.0714 |

5 | 70#/65Mn | (-0.12, 0) | 80-100 | 4 layers 1 core | 6.8 | 0.1116 |

5.2 | 304 stainless steel wire | (-0.12, 0) | 80-100 | 5 layers 1 core | 6 | 0.1207 |

6(normal) | 70#/65Mn | (-0.15, 0) | 90-110 | 6 layers 1 core | 6.6 | 0.1606 |

6.35 | 70#/65Mn | (-0.15, 0) | 140-160 | 4 layers 1 core | 15 | 0.1799 |

6.5 | brass coated steel wire | (-0.15, 0) | 100-120 | 7 layers 1 core | 9.5 | 0.1885 |

7 | 304 stainless steel wire | (-0.15, 0) | 140-160 | 5 layers 1 core | 16 | 0.2186 |

8(all black) | 70#/65Mn | (-0.15, 0) | 100-120 | 5 layers 1 core | 37 | 0.2856 |

8(5 brass coated | brass coated steel wire+70# | (-0.15, 0) | 140-160 | 5 layers 1 core | 30 | 0.2856 |

9 | 70#/65Mn | (-0.15, 0) | 180-200 | 4 layers 1 core | 42 | 0.3614 |

9.15(high speed) | 70#/65Mn | (-0.15, 0) | 240-260 | 5 layers 1 core | 45 | 0.3736 |

9.5(all brass coated) | brass coated steel wire+70# | (-0.15, 0) | 150-180 | 6 layers 1 core | 50 | 0.4027 |

10(normal) | 70#/65Mn | (-0.18, 0) | 240-260 | 4 layers 1 core | 50 | 0.4462 |

12(normal) | 70#/65Mn | (-0.18, 0) | 250-270 | 5 layers 1 core | 70 | 0.6425 |

13(normal) | 70#/65Mn | (-0.18, 0) | 260-280 | 5 layers 1 core | 110 | 0.7541 |

14(normal) | 70#/65Mn | (-0.18, 0) | 280-300 | 5 layers 1 core | 90 | 0.8746 |

15(normal) | 70#/65Mn | (-0.18, 0) | 320-340 | 5 layers 1 core | 120 | 1.0040 |

16(normal) | 70#/65Mn | (-0.18, 0) | 340-360 | 5 layers 1 core | 180 | 1.1423 |

18(normal) | 70#/65Mn | (-0.18, 0) | 450-480 | 5 layers 1 core | 210 | 1.4457 |

20(normal) | 70#/65Mn | (-0.25, 0) | 650-700/1000-1100 | 5 layers 1 core | 360 | 1.7848 |

22(normal) | 70#/65Mn | (-0.25, 0) | 1000-1100 | 5 layers 1 core | 400 | 2.1596 |

25 | 70#/65Mn | (-0.2,0.3) | 900-1100 | 10 layers 1 core | 570 | 2.7888 |

26 | 70#/65Mn | (-0.3,0.3) | 900-1100 | 7 layers 1 core | 950 | 3.0163 |

27(normal) | 70#/65Mn | (-0.5,0) | 900-1100 | 7 layers 1 core | 520 | 3.2528 |

32(normal) | 70#/65Mn | (-0.5,0) | 1000-1200 | 9 layers 1 core | 680 | 4.5691 |

40 | 70#/65Mn | (-0.5,0) | 1000-1200 | 10 layers 1 core | 800 | 7.1392 |

48 | 70#/65Mn | (-1, 0) | 1000-1200 | 12 layers 1 core | 1500 | 10.2804 |

Key Features

Smooth & Flexible Power Transmission

Designed with high elasticity and bending capability, the flexible drive delivers consistent torque even when routed through curves or tight spaces, ensuring stable and precise operation.

High Wear Resistance & Long Service Life

Constructed from wear-resistant inner cores and reinforced outer sheaths, this flexible drive withstands repeated rotation and friction in demanding drilling environments.

Wide Compatibility with Electric Drills

Compatible with most standard electric drills and rotary tools, making it a practical and versatile accessory for professional and home users.

Customizable Lengths & Specifications

Available in various lengths, diameters, and connector types. Custom flexible drives can be manufactured to match specific drill models or application requirements.

Easy Installation & Maintenance

Simple to install and remove, allowing quick replacement or adjustment with minimal downtime during work.

Applications

Applications

Electric Drill Extension Drive

Ideal for drilling or fastening in corners, narrow gaps, and hard-to-reach areas.Metal, Wood & Plastic Processing

Suitable for light drilling, polishing, grinding, and finishing tasks.Equipment Maintenance & Repair

Helps improve accessibility and efficiency during machinery servicing.Construction & Installation Work

Enhances flexibility and precision in on-site drilling operations.DIY & Workshop Use

A practical tool for home improvement, hobby projects, and small workshops.

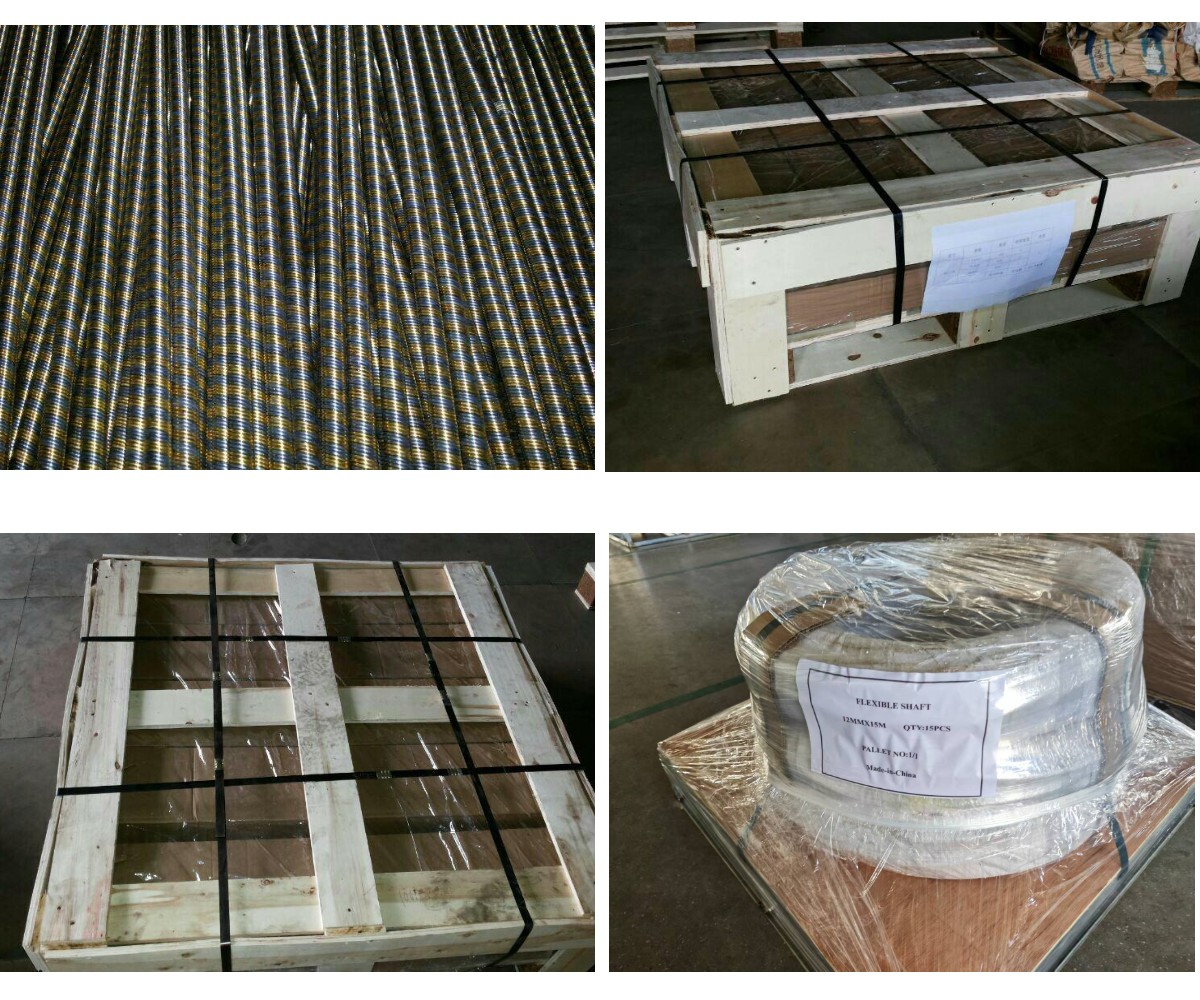

Our workshop

Why Choose Our Flexible Drive for Electric Drill?

Over 30 years of manufacturing experience in flexible drive shaft technology

Custom solutions available for length, torque capacity, and fittings

Low MOQ to support small orders, testing, and OEM projects

Fast production & delivery for stable supply chain performance

Strict quality inspection ensures smooth rotation, durability, and safety

Our package