Flexible Motor Shaft

1. 32 Years experience .Can accept specialized customized products

2. Low MOQ.Short delivery time

3. Smooth,flexible ,high elasticity.wear-resisting

Product Introduction

The Flexible Motor Shaft is a precision-engineered mechanical component designed to transmit rotary power from an electric motor to the driven equipment where alignment constraints, space limitations, or bending paths exist. By combining flexibility with stable torque transmission, it enables smooth and efficient power delivery in applications that require both adaptability and durability.

Manufactured from high-strength spring steel or alloy wire with advanced winding technology, our flexible motor shafts provide excellent torsional stability, wear resistance, and long service life. They are widely used in concrete vibrators, electric drills, polishing machines, grinding tools, cleaning equipment, and other motor-driven industrial or construction tools.

PRODUCT SPECIFICATION PARAMETER FOR PART OF OUR PRODUCTS | ||||||

Flexible shaft | Material | Tolerance(mm) | Bending Diameter (mm) | Layer | Max Failure Torque | Weight |

0.9 | 304 stainless steel wire | (-0.05, 0) | 10-20 | 3 layers 1 core | 0.5 | 0.0036 |

1.5 | 304 stainless steel wire | (-0.1, 0) | 20-30 | 3 layers 1 core | 1.05 | 0.0100 |

2 | 304 stainless steel wire | (-0.1, 0) | 30-40 | 3 layers 1 core | 1.3 | 0.0178 |

3.2 | brass coated steel wire | (-0.1, 0) | 40-60 | 4 layers 1 core | 2.8 | 0.0457 |

4 | 304 stainless steel wire | (-0.1, 0) | 60-80 | 4 layers 1 core | 5.2 | 0.0714 |

5 | 70#/65Mn | (-0.12, 0) | 80-100 | 4 layers 1 core | 6.8 | 0.1116 |

5.2 | 304 stainless steel wire | (-0.12, 0) | 80-100 | 5 layers 1 core | 6 | 0.1207 |

6(normal) | 70#/65Mn | (-0.15, 0) | 90-110 | 6 layers 1 core | 6.6 | 0.1606 |

6.35 | 70#/65Mn | (-0.15, 0) | 140-160 | 4 layers 1 core | 15 | 0.1799 |

6.5 | brass coated steel wire | (-0.15, 0) | 100-120 | 7 layers 1 core | 9.5 | 0.1885 |

7 | 304 stainless steel wire | (-0.15, 0) | 140-160 | 5 layers 1 core | 16 | 0.2186 |

8(all black) | 70#/65Mn | (-0.15, 0) | 100-120 | 5 layers 1 core | 37 | 0.2856 |

8(5 brass coated | brass coated steel wire+70# | (-0.15, 0) | 140-160 | 5 layers 1 core | 30 | 0.2856 |

9 | 70#/65Mn | (-0.15, 0) | 180-200 | 4 layers 1 core | 42 | 0.3614 |

9.15(high speed) | 70#/65Mn | (-0.15, 0) | 240-260 | 5 layers 1 core | 45 | 0.3736 |

9.5(all brass coated) | brass coated steel wire+70# | (-0.15, 0) | 150-180 | 6 layers 1 core | 50 | 0.4027 |

10(normal) | 70#/65Mn | (-0.18, 0) | 240-260 | 4 layers 1 core | 50 | 0.4462 |

12(normal) | 70#/65Mn | (-0.18, 0) | 250-270 | 5 layers 1 core | 70 | 0.6425 |

13(normal) | 70#/65Mn | (-0.18, 0) | 260-280 | 5 layers 1 core | 110 | 0.7541 |

14(normal) | 70#/65Mn | (-0.18, 0) | 280-300 | 5 layers 1 core | 90 | 0.8746 |

15(normal) | 70#/65Mn | (-0.18, 0) | 320-340 | 5 layers 1 core | 120 | 1.0040 |

16(normal) | 70#/65Mn | (-0.18, 0) | 340-360 | 5 layers 1 core | 180 | 1.1423 |

18(normal) | 70#/65Mn | (-0.18, 0) | 450-480 | 5 layers 1 core | 210 | 1.4457 |

20(normal) | 70#/65Mn | (-0.25, 0) | 650-700/1000-1100 | 5 layers 1 core | 360 | 1.7848 |

22(normal) | 70#/65Mn | (-0.25, 0) | 1000-1100 | 5 layers 1 core | 400 | 2.1596 |

25 | 70#/65Mn | (-0.2,0.3) | 900-1100 | 10 layers 1 core | 570 | 2.7888 |

26 | 70#/65Mn | (-0.3,0.3) | 900-1100 | 7 layers 1 core | 950 | 3.0163 |

27(normal) | 70#/65Mn | (-0.5,0) | 900-1100 | 7 layers 1 core | 520 | 3.2528 |

32(normal) | 70#/65Mn | (-0.5,0) | 1000-1200 | 9 layers 1 core | 680 | 4.5691 |

40 | 70#/65Mn | (-0.5,0) | 1000-1200 | 10 layers 1 core | 800 | 7.1392 |

48 | 70#/65Mn | (-1, 0) | 1000-1200 | 12 layers 1 core | 1500 | 10.2804 |

Key Features of Flexible Motor Shaft

Smooth & Stable Power Transmission

Designed to maintain consistent rotational output, even when the shaft operates under curved routing or slight misalignment between the motor and the driven unit.

High Flexibility with Strong Torque Capacity

Optimized wire structure allows the shaft to bend smoothly without compromising torque transmission, ensuring reliable operation in confined or complex installations.

Excellent Wear Resistance & Durability

Made from wear-resistant materials and heat-treated for strength, suitable for long-term use in dusty, high-load, or high-frequency working environments.

Customizable Specifications

Flexible motor shafts can be customized in length, diameter, end fittings, rotation speed, and torque capacity, ensuring compatibility with different motor types and equipment designs.

Easy Installation & Maintenance

Simple structure allows quick installation, replacement, and maintenance, reducing downtime and improving overall operational efficiency.

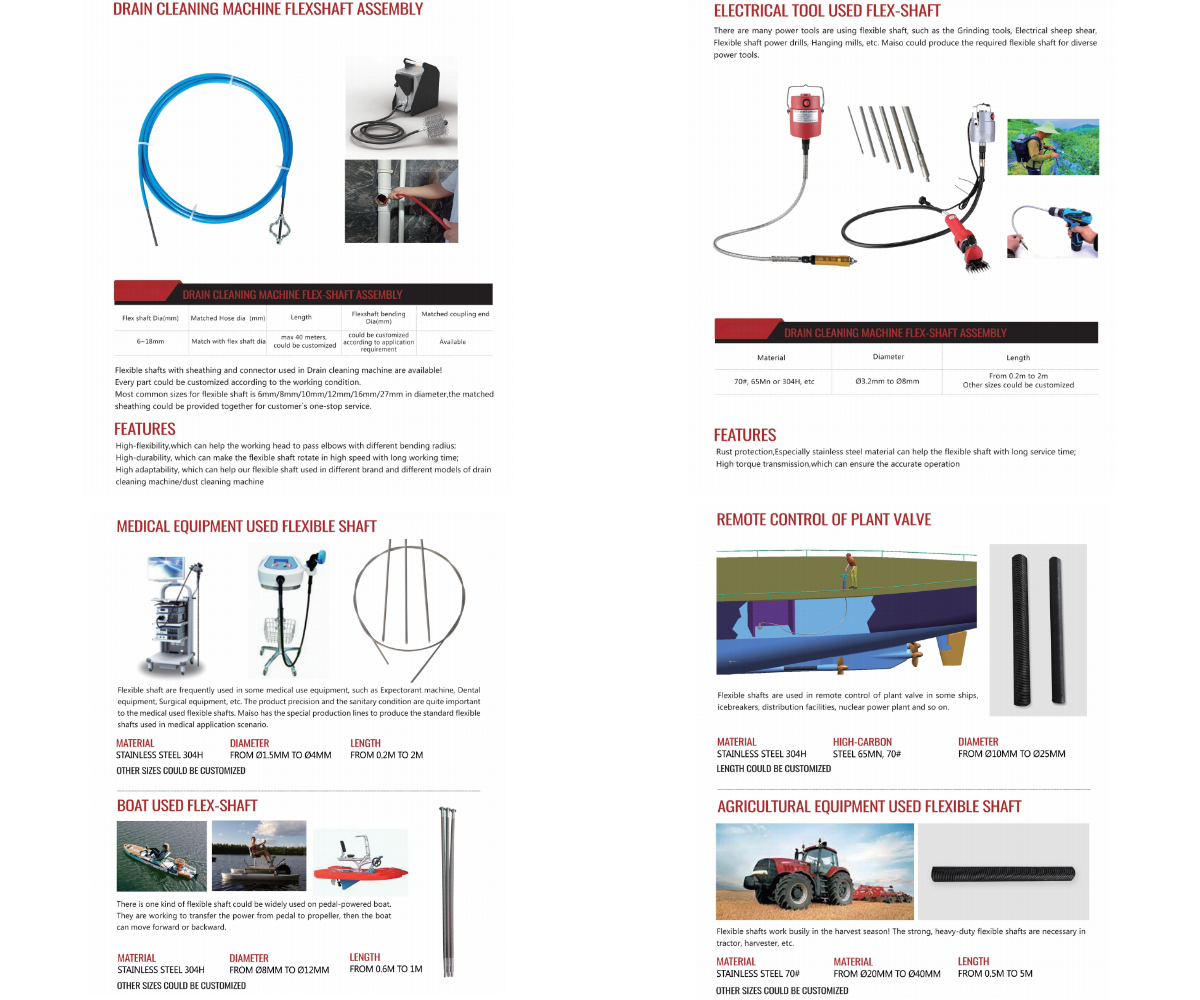

Typical Applications

Electric concrete vibrators

Electric drills and handheld power tools

Grinding and polishing machines

Industrial cleaning and deburring tools

Small motor-driven machinery with offset or flexible transmission requirements

Applications

Why Choose Our Flexible Motor Shafts?

32+ Years of Manufacturing Experience

Specialized in flexible shaft and power transmission component production for global industrial markets.OEM & Custom Solutions Available

Tailored designs to match your motor power, speed, and application requirements.Low MOQ Support

Suitable for distributors, equipment manufacturers, R&D projects, and small-batch procurement.Fast Production & Delivery

Efficient manufacturing process ensures short lead times and stable supply.Strict Quality Control

Each flexible motor shaft is tested for flexibility, torque performance, and durability before shipment.

Our workshop

Our package