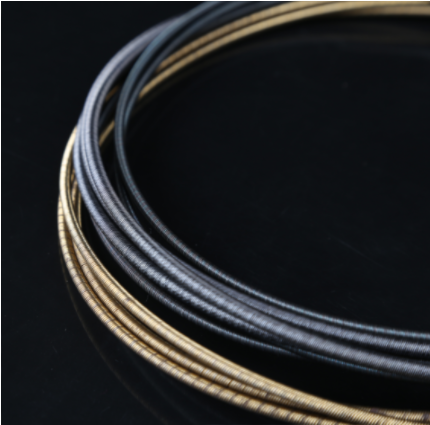

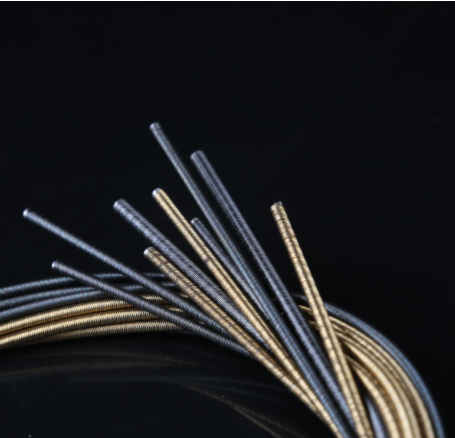

Flexible Drive Shaft Cable

Flexible Shaft production center in China

Generations technical team R&D enthusiasm and ability

32 Years experience focusing on Flexible shafts

Hours timely responded service team

100%Ensured premium quality

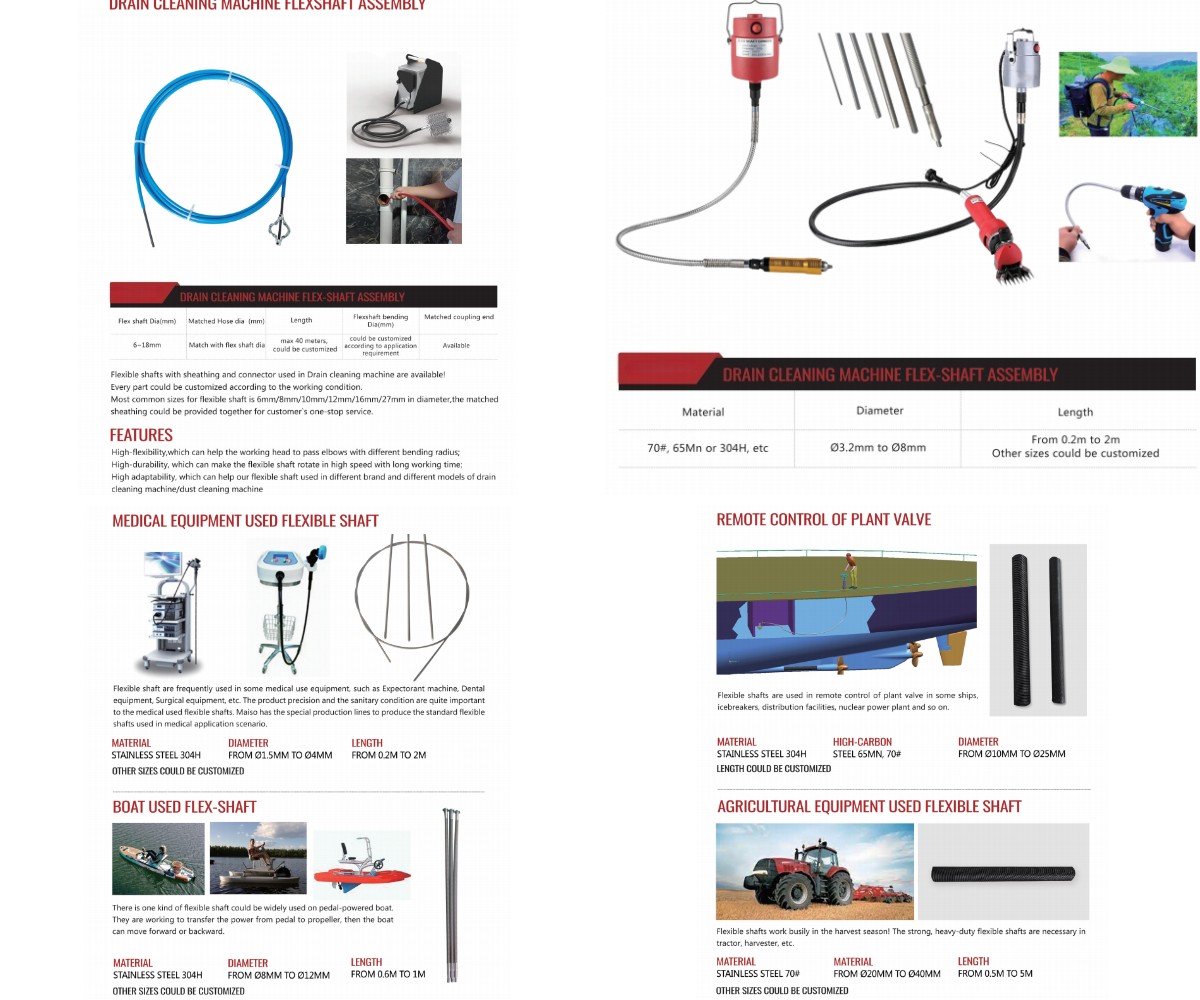

Product Introduction

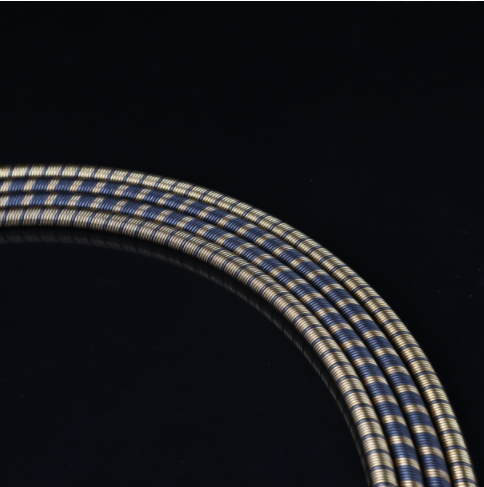

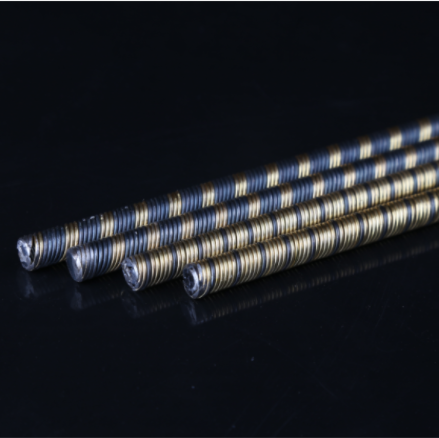

The Flexible Drive Shaft Cable is a high-performance, precision-engineered component designed to efficiently transmit rotary motion in applications where flexibility, durability, and smooth power transfer are essential. Made from premium materials, our flexible drive shaft cables provide excellent wear resistance, superior elasticity, and enhanced bending capability, making them ideal for a wide range of industrial and construction tools. Whether used in submersible pumps, power tools, or concrete vibrators, these cables deliver reliable, long-lasting performance under demanding conditions.

PRODUCT SPECIFICATION PARAMETER FOR PART OF OUR PRODUCTS

Flexible shaft | Material | Tolerance(mm) | Bending Diameter (mm) | Layer | Max Failure Torque | Weight |

0.9 | 304 stainless steel wire | (-0.05, 0) | 10-20 | 3 layers 1 core | 0.5 | 0.0036 |

1.5 | 304 stainless steel wire | (-0.1, 0) | 20-30 | 3 layers 1 core | 1.05 | 0.0100 |

2 | 304 stainless steel wire | (-0.1, 0) | 30-40 | 3 layers 1 core | 1.3 | 0.0178 |

3.2 | brass coated steel wire | (-0.1, 0) | 40-60 | 4 layers 1 core | 2.8 | 0.0457 |

4 | 304 stainless steel wire | (-0.1, 0) | 60-80 | 4 layers 1 core | 5.2 | 0.0714 |

5 | 70#/65Mn | (-0.12, 0) | 80-100 | 4 layers 1 core | 6.8 | 0.1116 |

5.2 | 304 stainless steel wire | (-0.12, 0) | 80-100 | 5 layers 1 core | 6 | 0.1207 |

6(normal) | 70#/65Mn | (-0.15, 0) | 90-110 | 6 layers 1 core | 6.6 | 0.1606 |

6.35 | 70#/65Mn | (-0.15, 0) | 140-160 | 4 layers 1 core | 15 | 0.1799 |

6.5 | brass coated steel wire | (-0.15, 0) | 100-120 | 7 layers 1 core | 9.5 | 0.1885 |

7 | 304 stainless steel wire | (-0.15, 0) | 140-160 | 5 layers 1 core | 16 | 0.2186 |

8(all black) | 70#/65Mn | (-0.15, 0) | 100-120 | 5 layers 1 core | 37 | 0.2856 |

8(5 brass coated | brass coated steel wire+70# | (-0.15, 0) | 140-160 | 5 layers 1 core | 30 | 0.2856 |

9 | 70#/65Mn | (-0.15, 0) | 180-200 | 4 layers 1 core | 42 | 0.3614 |

9.15(high speed) | 70#/65Mn | (-0.15, 0) | 240-260 | 5 layers 1 core | 45 | 0.3736 |

9.5(all brass coated) | brass coated steel wire+70# | (-0.15, 0) | 150-180 | 6 layers 1 core | 50 | 0.4027 |

10(normal) | 70#/65Mn | (-0.18, 0) | 240-260 | 4 layers 1 core | 50 | 0.4462 |

12(normal) | 70#/65Mn | (-0.18, 0) | 250-270 | 5 layers 1 core | 70 | 0.6425 |

13(normal) | 70#/65Mn | (-0.18, 0) | 260-280 | 5 layers 1 core | 110 | 0.7541 |

14(normal) | 70#/65Mn | (-0.18, 0) | 280-300 | 5 layers 1 core | 90 | 0.8746 |

15(normal) | 70#/65Mn | (-0.18, 0) | 320-340 | 5 layers 1 core | 120 | 1.0040 |

16(normal) | 70#/65Mn | (-0.18, 0) | 340-360 | 5 layers 1 core | 180 | 1.1423 |

18(normal) | 70#/65Mn | (-0.18, 0) | 450-480 | 5 layers 1 core | 210 | 1.4457 |

20(normal) | 70#/65Mn | (-0.25, 0) | 650-700/1000-1100 | 5 layers 1 core | 360 | 1.7848 |

22(normal) | 70#/65Mn | (-0.25, 0) | 1000-1100 | 5 layers 1 core | 400 | 2.1596 |

25 | 70#/65Mn | (-0.2,0.3) | 900-1100 | 10 layers 1 core | 570 | 2.7888 |

26 | 70#/65Mn | (-0.3,0.3) | 900-1100 | 7 layers 1 core | 950 | 3.0163 |

27(normal) | 70#/65Mn | (-0.5,0) | 900-1100 | 7 layers 1 core | 520 | 3.2528 |

32(normal) | 70#/65Mn | (-0.5,0) | 1000-1200 | 9 layers 1 core | 680 | 4.5691 |

40 | 70#/65Mn | (-0.5,0) | 1000-1200 | 10 layers 1 core | 800 | 7.1392 |

48 | 70#/65Mn | (-1, 0) | 1000-1200 | 12 layers 1 core | 1500 | 10.2804 |

Features

Smooth and Flexible Transmission

Engineered for high flexibility and elasticity, allowing seamless power transfer even under high-torque or curved routing conditions.Superior Wear Resistance

Constructed from durable, wear-resistant materials to ensure long service life, even in harsh environments such as concrete work or heavy-duty drilling.Customizable Solutions

With over 32 years of manufacturing experience, we provide fully customizable flexible drive shaft cables to meet your unique length, diameter, fitting, or performance requirements.Low MOQ and Fast Delivery

Supports small-batch orders with short lead times, allowing flexible and responsive procurement for your projects.Easy Maintenance and Replacement

Designed for quick assembly and disassembly, reducing downtime and making field repairs faster and more efficient.

Why Choose Our Flexible Drive Shaft Cables?

32+ Years of Expertise – Extensive experience in designing and manufacturing flexible drive solutions for global industrial markets.

Tailored Solutions – Customizable cables for diameter, length, fittings, and torque capacity.

Low Minimum Orders – Supports startups, R&D, and flexible supply strategies.

Fast Delivery and Responsive Service – Ensures project timelines are met without delays.

Strict Quality Control – Each cable is tested for durability and performance before shipment.