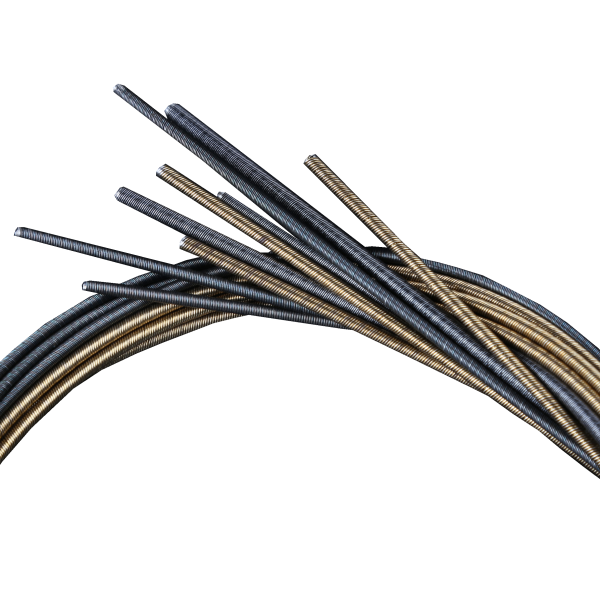

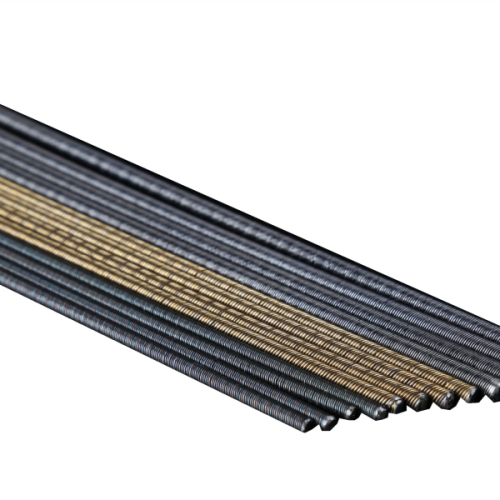

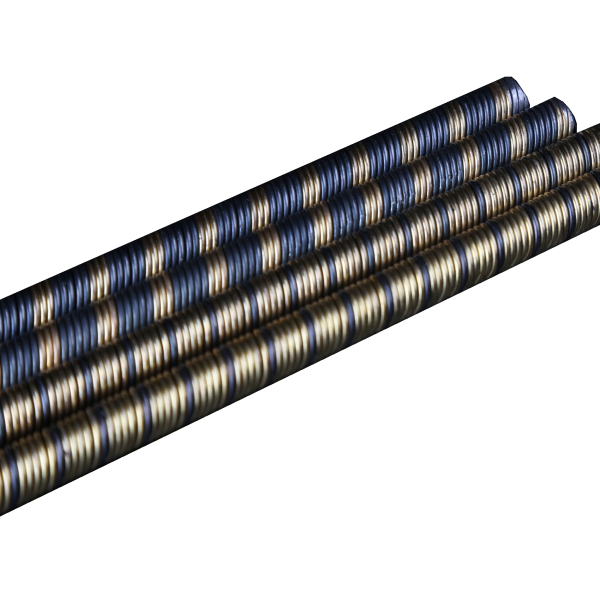

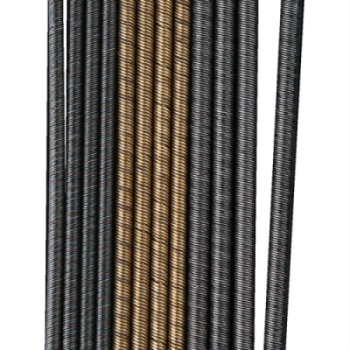

Good Flexible Drive Shaft

1. 32 Years experience .Can accept specialized customized products

2. Low MOQ.Short delivery time

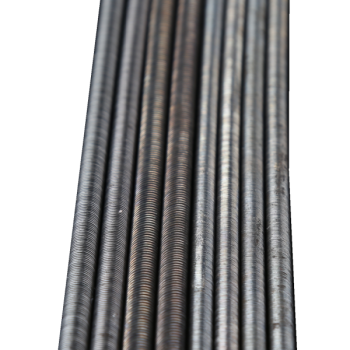

3. Smooth,flexible ,high elasticity.wear-resisting

Product Introduction

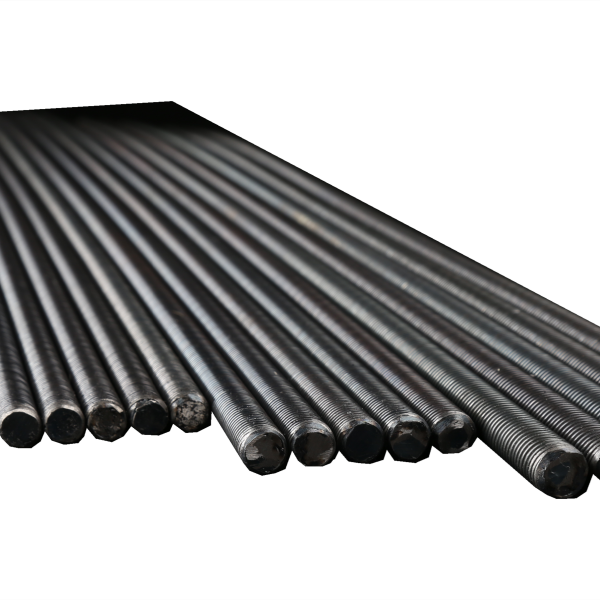

The Good Flexible Drive Shaft is a reliable and high-quality power transmission component designed for applications that require flexibility, durability, and stable torque delivery. Manufactured with carefully selected materials and precision processes, this flexible drive shaft provides smooth rotation, excellent bending performance, and long service life.

It is widely used in concrete vibrators, submersible pumps, power tools, and various industrial equipment, delivering consistent performance even in demanding working environments.

PRODUCT SPECIFICATION PARAMETER FOR PART OF OUR PRODUCTS

Flexible shaft | Material | Tolerance(mm) | Bending Diameter (mm) | Layer | Max Failure Torque | Weight |

0.9 | 304 stainless steel wire | (-0.05, 0) | 10-20 | 3 layers 1 core | 0.5 | 0.0036 |

1.5 | 304 stainless steel wire | (-0.1, 0) | 20-30 | 3 layers 1 core | 1.05 | 0.0100 |

2 | 304 stainless steel wire | (-0.1, 0) | 30-40 | 3 layers 1 core | 1.3 | 0.0178 |

3.2 | brass coated steel wire | (-0.1, 0) | 40-60 | 4 layers 1 core | 2.8 | 0.0457 |

4 | 304 stainless steel wire | (-0.1, 0) | 60-80 | 4 layers 1 core | 5.2 | 0.0714 |

5 | 70#/65Mn | (-0.12, 0) | 80-100 | 4 layers 1 core | 6.8 | 0.1116 |

5.2 | 304 stainless steel wire | (-0.12, 0) | 80-100 | 5 layers 1 core | 6 | 0.1207 |

6(normal) | 70#/65Mn | (-0.15, 0) | 90-110 | 6 layers 1 core | 6.6 | 0.1606 |

6.35 | 70#/65Mn | (-0.15, 0) | 140-160 | 4 layers 1 core | 15 | 0.1799 |

6.5 | brass coated steel wire | (-0.15, 0) | 100-120 | 7 layers 1 core | 9.5 | 0.1885 |

7 | 304 stainless steel wire | (-0.15, 0) | 140-160 | 5 layers 1 core | 16 | 0.2186 |

8(all black) | 70#/65Mn | (-0.15, 0) | 100-120 | 5 layers 1 core | 37 | 0.2856 |

8(5 brass coated | brass coated steel wire+70# | (-0.15, 0) | 140-160 | 5 layers 1 core | 30 | 0.2856 |

9 | 70#/65Mn | (-0.15, 0) | 180-200 | 4 layers 1 core | 42 | 0.3614 |

9.15(high speed) | 70#/65Mn | (-0.15, 0) | 240-260 | 5 layers 1 core | 45 | 0.3736 |

9.5(all brass coated) | brass coated steel wire+70# | (-0.15, 0) | 150-180 | 6 layers 1 core | 50 | 0.4027 |

10(normal) | 70#/65Mn | (-0.18, 0) | 240-260 | 4 layers 1 core | 50 | 0.4462 |

12(normal) | 70#/65Mn | (-0.18, 0) | 250-270 | 5 layers 1 core | 70 | 0.6425 |

13(normal) | 70#/65Mn | (-0.18, 0) | 260-280 | 5 layers 1 core | 110 | 0.7541 |

14(normal) | 70#/65Mn | (-0.18, 0) | 280-300 | 5 layers 1 core | 90 | 0.8746 |

15(normal) | 70#/65Mn | (-0.18, 0) | 320-340 | 5 layers 1 core | 120 | 1.0040 |

16(normal) | 70#/65Mn | (-0.18, 0) | 340-360 | 5 layers 1 core | 180 | 1.1423 |

18(normal) | 70#/65Mn | (-0.18, 0) | 450-480 | 5 layers 1 core | 210 | 1.4457 |

20(normal) | 70#/65Mn | (-0.25, 0) | 650-700/1000-1100 | 5 layers 1 core | 360 | 1.7848 |

22(normal) | 70#/65Mn | (-0.25, 0) | 1000-1100 | 5 layers 1 core | 400 | 2.1596 |

25 | 70#/65Mn | (-0.2,0.3) | 900-1100 | 10 layers 1 core | 570 | 2.7888 |

26 | 70#/65Mn | (-0.3,0.3) | 900-1100 | 7 layers 1 core | 950 | 3.0163 |

27(normal) | 70#/65Mn | (-0.5,0) | 900-1100 | 7 layers 1 core | 520 | 3.2528 |

32(normal) | 70#/65Mn | (-0.5,0) | 1000-1200 | 9 layers 1 core | 680 | 4.5691 |

40 | 70#/65Mn | (-0.5,0) | 1000-1200 | 10 layers 1 core | 800 | 7.1392 |

48 | 70#/65Mn | (-1, 0) | 1000-1200 | 12 layers 1 core | 1500 | 10.2804 |

Our workshop

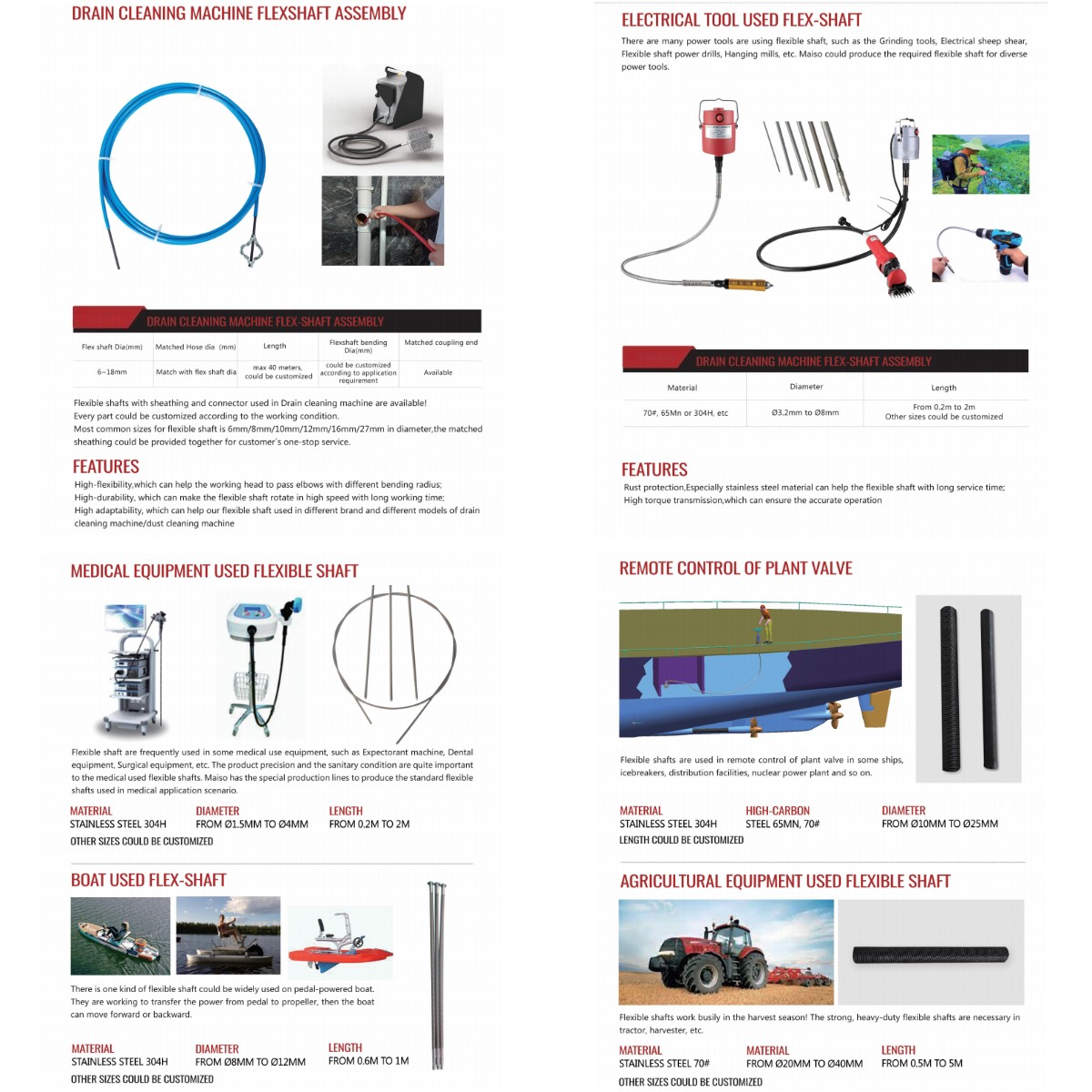

Application

Key Features

Smooth & Stable Power Transmission

Designed with high elasticity to ensure smooth and continuous torque transfer, even under high-load or curved installation conditions.

Excellent Wear Resistance

Made from wear-resistant materials to withstand intensive use in harsh environments such as concrete vibration and heavy-duty industrial operations.

Flexible Customization Options

Backed by 32 years of manufacturing experience, we offer customized flexible drive shafts based on required length, diameter, end fittings, and torque capacity.

Low MOQ & Fast Lead Time

Supports small quantity orders with efficient production schedules to ensure quick delivery and flexible procurement.

Easy Installation & Maintenance

Simple structure allows fast assembly and replacement, minimizing downtime and improving work efficiency.

Our workshop

Why Choose Our Good Flexible Drive Shaft?

Over 32 years of expertise in flexible drive shaft manufacturing

OEM & customized solutions available to match different applications

Low minimum order quantity, ideal for testing and small projects

Fast response and on-time delivery to support your supply chain

Strict quality control to guarantee durability and consistent performance

Our package

Contact with us